Automatic Vertical Cartoning Machine

Product Details:

- Power Supply 1 Phase, 230 V, 50 Hz

- Application Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products,

- Features Automatic Product Feeding System, Barcode & Serialization Integration, Rejection System, Hot Melt Glue System with Precision Control, Provision for Bottom Lock, Integrated Leaflet Insertion, Polycarbonate Guard

- Noise Level 85 db

- Usage Carton packaging for various industries. e.g. Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products,

- Type Packaging Line

- Material SS-304

- Click to View more

Automatic Vertical Cartoning Machine Price And Quantity

- 1 Unit

- 2400000.00 - 2400000.00 INR/Unit

- 2400000 INR/Unit

Automatic Vertical Cartoning Machine Product Specifications

- Silver

- SS-304

- Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products

- Packaging Line

- 1.4 X 1.9 X 1.26 Meter (m)

- Highly Efficient Less Power Consumable Durable

- 230 Volt (v)

- 1 Horsepower (HP)

- 1 Phase, 230 V, 50 Hz

- Automatic Product Feeding System, Barcode & Serialization Integration, Rejection System, Hot Melt Glue System with Precision Control, Provision for Bottom Lock, Integrated Leaflet Insertion, Polycarbonate Guard

- 85 db

- Other

- 500 Kilograms (kg)

- Carton packaging for various industries. e.g. Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products

- 50 Pcs/hr

- 1 Year

- PLC Control

- Mechanical

- No

- Automatic

Automatic Vertical Cartoning Machine Trade Information

- Cash in Advance (CID)

- 1 Unit Per Month

- 45 Days

- Contact us for information regarding our sample policy

- Wooden Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015, GMP and IEC Certifications

Product Description

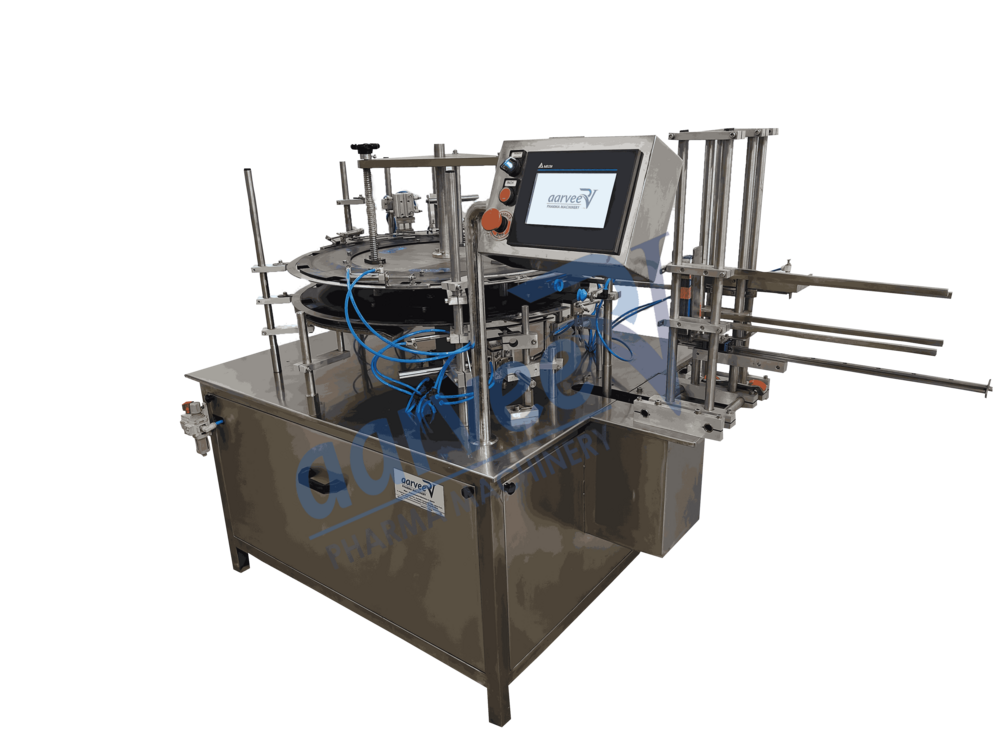

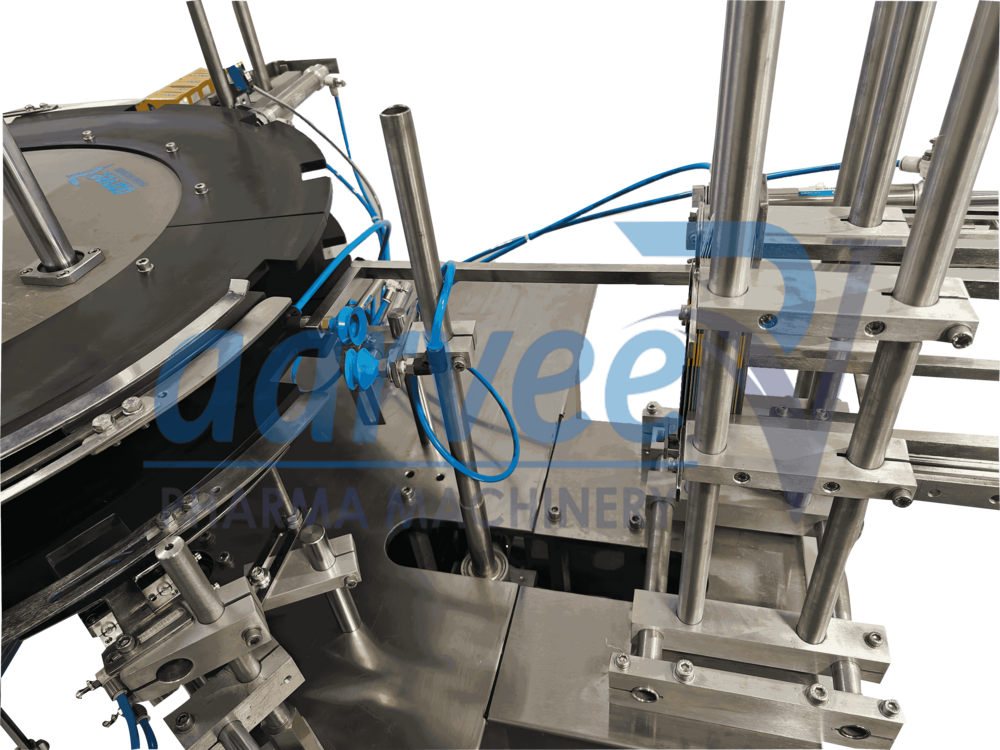

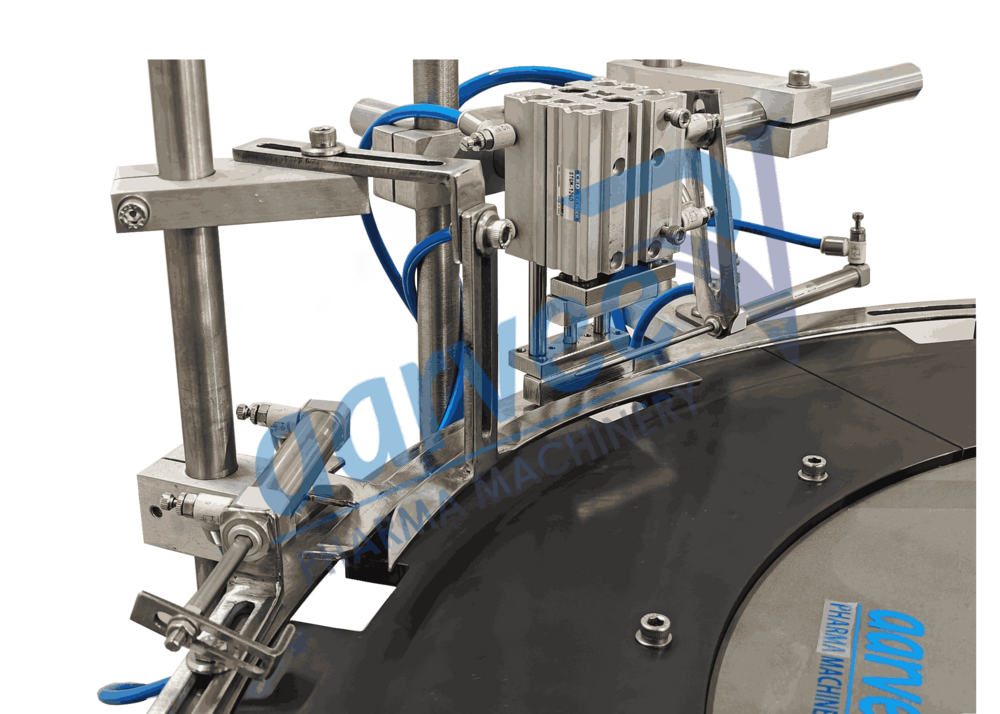

Automatic Vertical Cartoning Machine offered by AARVEE PHARMA MACHINERY, is a cost-effective and versatile cartoner machine engineered for medium-speed packaging applications across the pharmaceutical, food, cosmetics, and consumer goods industries. Designed to provide efficient and reliable vertical cartoning, this machine ensures a streamlined packaging process while maintaining an economical footprint. With multiple carton closing options, including tuck-in and hot-melt glue sealing, it offers flexibility to accommodate diverse packaging needs. Featuring a user-friendly PLC control system with an intuitive HMI, operators benefit from seamless operation, real-time monitoring and quick adjustments, reducing downtime and optimizing efficiency. Built for reliability, ease of maintenance and affordability, this budget-friendly Rotary Vertical Cartoning Machine is the perfect solution for manufacturers seeking a space-saving, efficient and cost-effective cartoning system that enhances productivity while maintaining superior packaging quality.

Key Features:

1. Medium-Speed Operation - Designed for efficient and reliable vertical cartoning in small to medium-scale production environments.

2. Compact and Space-Saving Design - Ideal for facilities with limited production space, ensuring seamless integration into existing lines.

3. Stainless Steel SS-304 Construction - Enhances machine durability and compliance with hygiene standards for pharmaceutical and food applications.

4. Customization for Different Carton Sizes - Adjustable guides and UHMW Material Starwheel to accommodate a variety of carton dimensions.

4. User-Friendly PLC Control System - Equipped with an intuitive HMI, enabling real-time monitoring, quick adjustments and simplified operation.

5. Easy Maintenance & Quick Changeover - Tool-less adjustment system allows fast format changes, reducing downtime and increasing productivity.

6. Cost-Effective Solution - Provides an economical yet efficient cartoning process for manufacturers seeking an affordable automation option.

7. Reliable and Sturdy Construction - Engineered for durability and long-term operation, minimizing operational disruptions.

Optional Features

1. Automatic Product Feeding System - Reduces manual labor by automating product loading for higher efficiency.

2. Barcode & Serialization Integration - Supports traceability and regulatory compliance by incorporating printing and scanning options.

3. Rejection System - Automatically Reject the empty cartons if operator missed to place the product into the carton

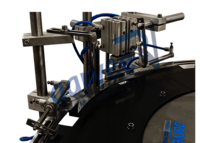

4. Hot Melt Glue System with Precision Control - Provides precise glue application to ensure secure carton sealing.

5. Provision for Bottom Lock / Gluing Cartons / Lock Bottom / Hanger Type Cartons

6. Integrated Leaflet Insertion - Ensures compliance with industry regulations, enhancing product presentation and traceability.

7. Polycarbonate Guard

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+