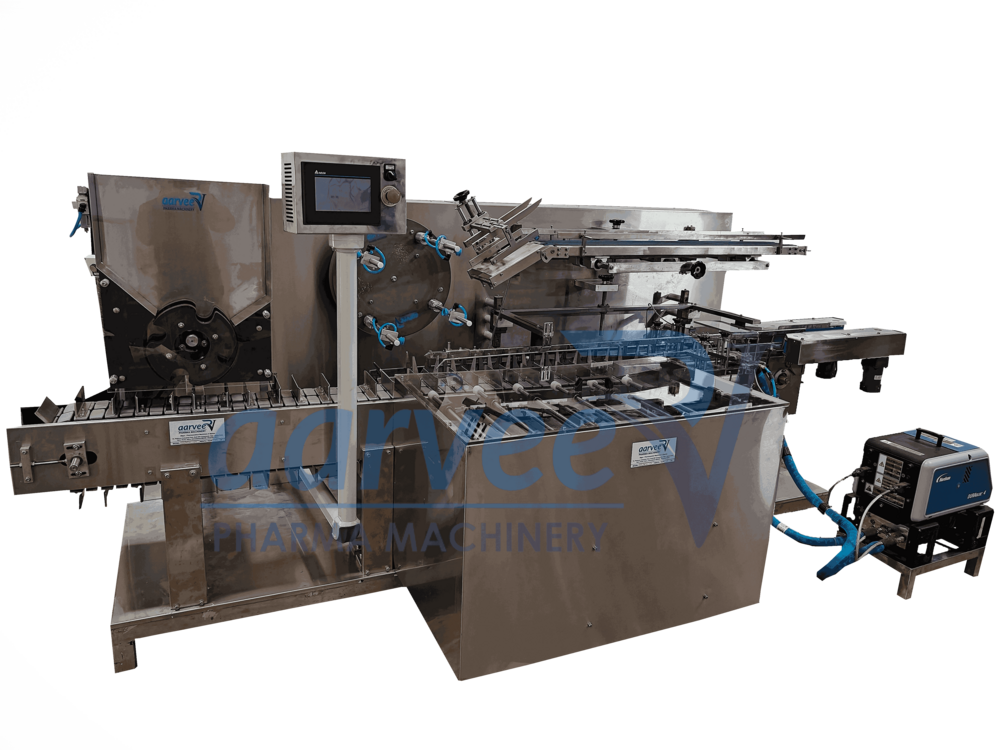

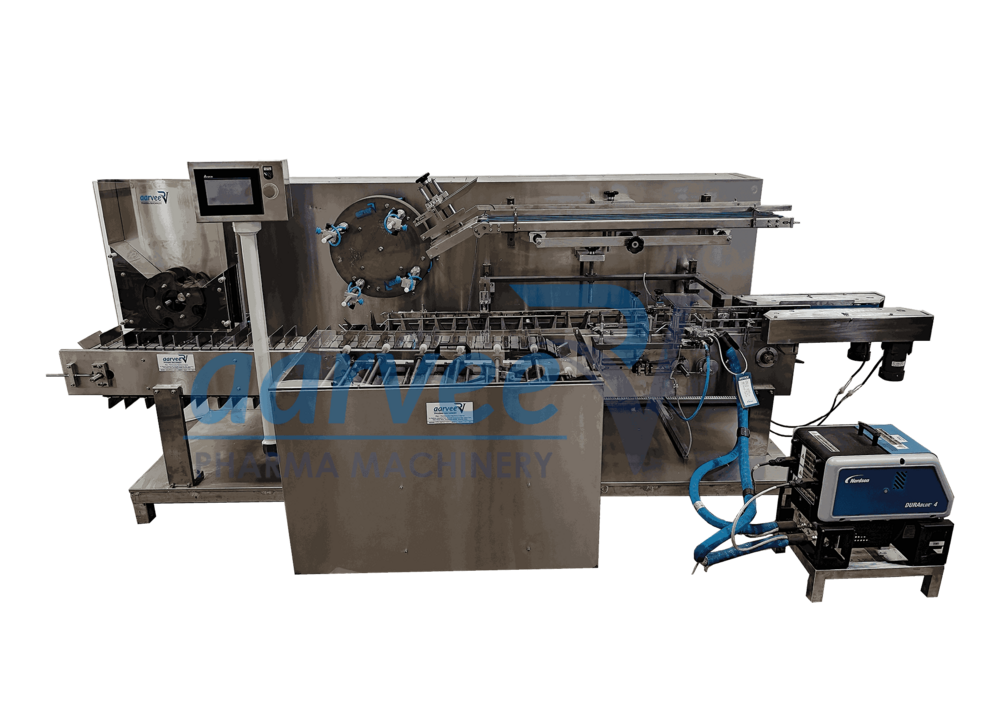

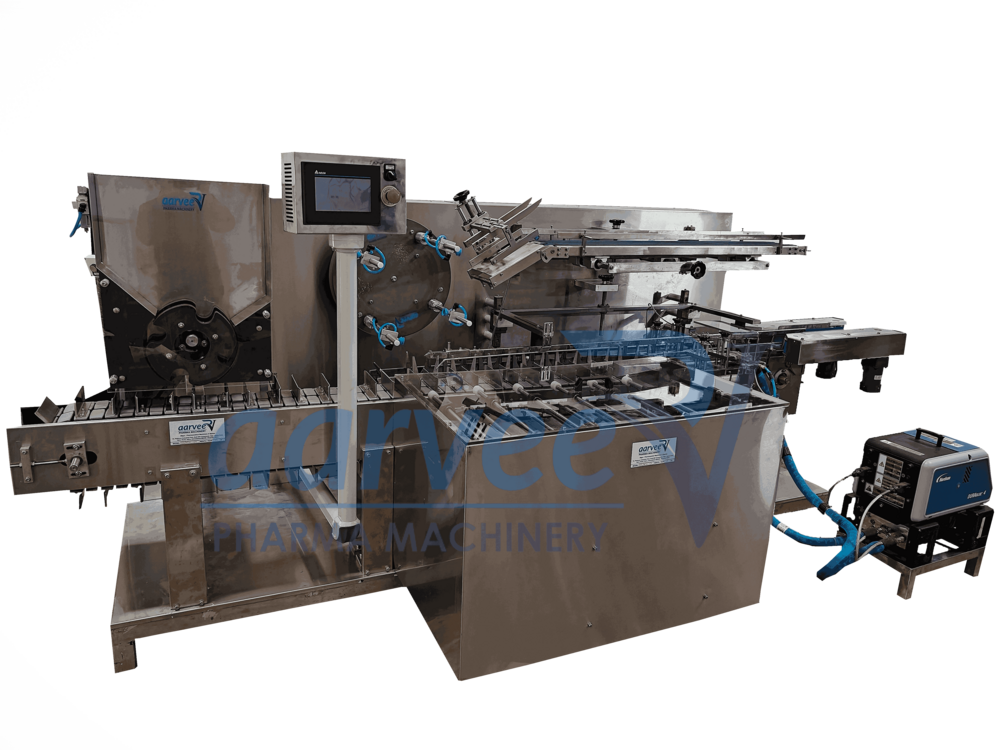

High Speed Cartoner

Product Details:

- Usage Carton packaging for various industries. e.g. Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products,

- Application Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products,

- Power Supply 1 Phase, 230 V, 50 Hz

- Noise Level 85 db

- Features Fully automated, high-precision operation, Robust mechanical pusher system, 4-arm rotary carton pick-up, Smart detection to avoid waste, Tuck-in or hot-melt glue sealing, Quick knob-type size changeover, Large 1200-carton magazine, Touchscreen HMI with PLC control, Safety sensors & fault detection, Optional printer, folder & vision system

- Type Packaging Line

- Material SS-304

- Click to View more

High Speed Cartoner Price And Quantity

- 1 Unit

- 2500000.00 INR/Unit

- 2500000.00 - 2500000.00 INR/Unit

High Speed Cartoner Product Specifications

- PLC Control

- Fully automated, high-precision operation, Robust mechanical pusher system, 4-arm rotary carton pick-up, Smart detection to avoid waste, Tuck-in or hot-melt glue sealing, Quick knob-type size changeover, Large 1200-carton magazine, Touchscreen HMI with PLC control, Safety sensors & fault detection, Optional printer, folder & vision system

- Silver

- 1 Year

- Mechanical

- 1 Horsepower (HP)

- Highly Efficient Less Power Consumable Durable

- Other

- Automatic

- 85 db

- 1 Phase, 230 V, 50 Hz

- 150 Pcs/hr

- Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products

- 230 Volt (v)

- 2000 Kilograms (kg)

- No

- 4.5 X 1.5 X 1.4 Meter (m)

- Other

- SS-304

- Packaging Line

- Carton packaging for various industries. e.g. Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products

High Speed Cartoner Trade Information

- Cash in Advance (CID)

- 1 Unit Per Month

- 45 Days

- Contact us for information regarding our sample policy

- Wooden Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015, GMP and IEC Certifications

Product Description

The Automatic High-Speed Cartoning Machine - offered by AARVEE PHARMA MACHINERY, is a fully automated and versatile cartoner machine designed to meet the demands of high-speed packaging operations across various industries. Operating in a continuous horizontal mode, it delivers exceptional speed and precision, achieving up to 300 cartons per minute (CPM) to maximize efficiency and productivity. This advanced cartonator machine seamlessly integrates essential functions such as product checking, carton pick-up, product insertion, carton closure, and carton discharge, ensuring smooth and error-free operation. Its robust mechanical-based pusher system guarantees precise product insertion into the carton, while multiple carton closing options, including tuck-in or hot-melt glue sealing, provide flexibility for diverse packaging requirements. Equipped with a user-friendly PLC control system and an intuitive HMI, it allows for real-time monitoring, quick adjustments and minimal downtime. Engineered for reliability, efficiency and compliance with stringent industry standards, this high-speed cartoning solution empowers manufacturers to optimize their packaging processes, enhance output and maintain a competitive edge in fast-paced production environments.

Key Features:

1. Fully automated operation ensuring high efficiency and precision.

2. Robust mechanical-based pusher system for reliable and consistent product insertion.

3. 4-arm rotary carton pick-up system for stable and precise carton erecting.

4. If the product is missing, the cartoner machine will not pick up the carton, preventing material waste.

5. No carton, no push function “ If the product is present but the carton is missing, the mechanical pusher will not activate and the product will be collected into a bin, preventing incomplete packaging.

7. Multiple carton closing options, including tuck-in or hot-melt glue sealing, providing flexibility for various applications.

8. Knob type adjustment for quick carton size changeover, minimizing downtime and increasing productivity.

10. Long carton magazine with up to 1200-carton capacity, reducing the need for frequent reloading and increasing operational efficiency.

11. User-friendly PLC control system with an intuitive touchscreen HMI for real-time monitoring and adjustments.

12. Equipped with safety sensors and fault detection systems, ensuring operational security and minimizing product loss.

13. Automatic Product Feeder Options e.g. Hopper/ Turn Table/ Blister Stacker /Pouch Stacker

Optional Features:

1. Integrated Inkjet Printer for Batch/Expiration Dates

2. Integrated Hot-Melt Dispensing System for the Gluing Type Cartons

3. Provision for Bottom Lock / Lock Bottom / Hanger Type Cartons

4. Integrated Leaflet Folding Device

5. Polycarbonate Guard

6. Integrated Weighing System for Product Quality Control

7. Automatic Bottle/Blister/Leaflet/Pouch Feeder Mechanism

8. Vision Inspection System for Barcode/Pharma Code Scanning

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+