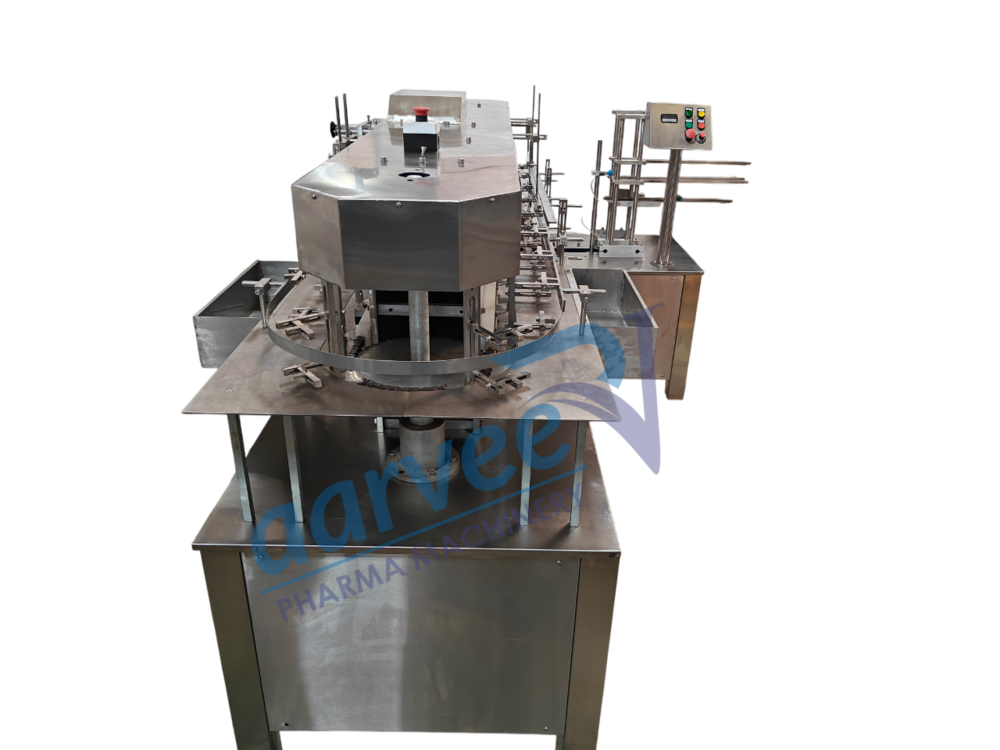

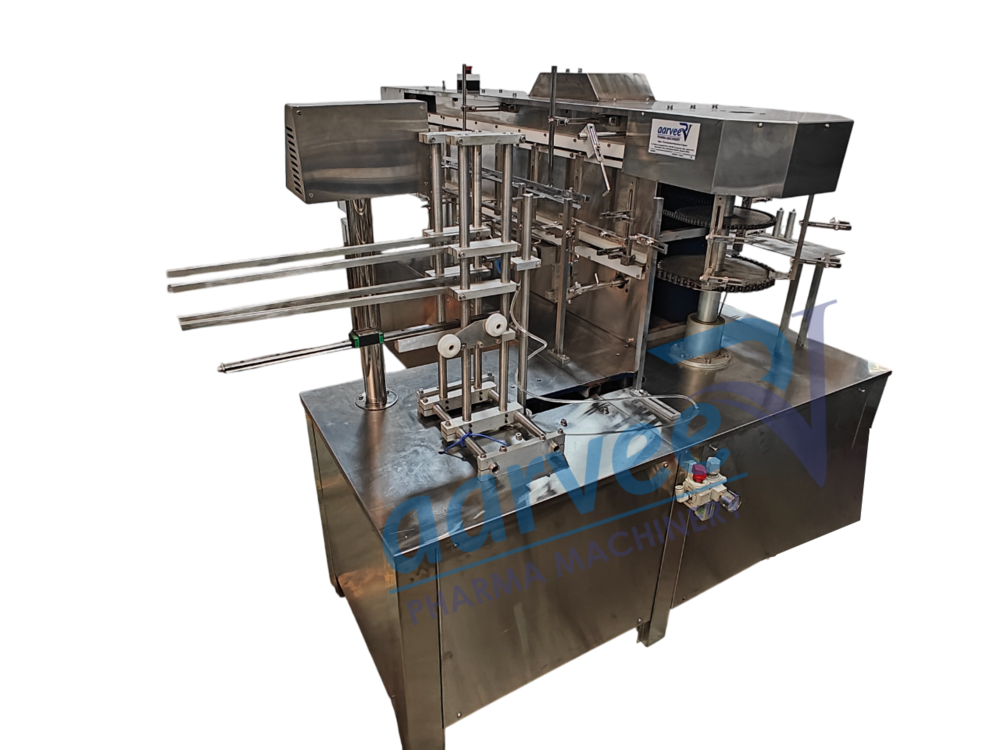

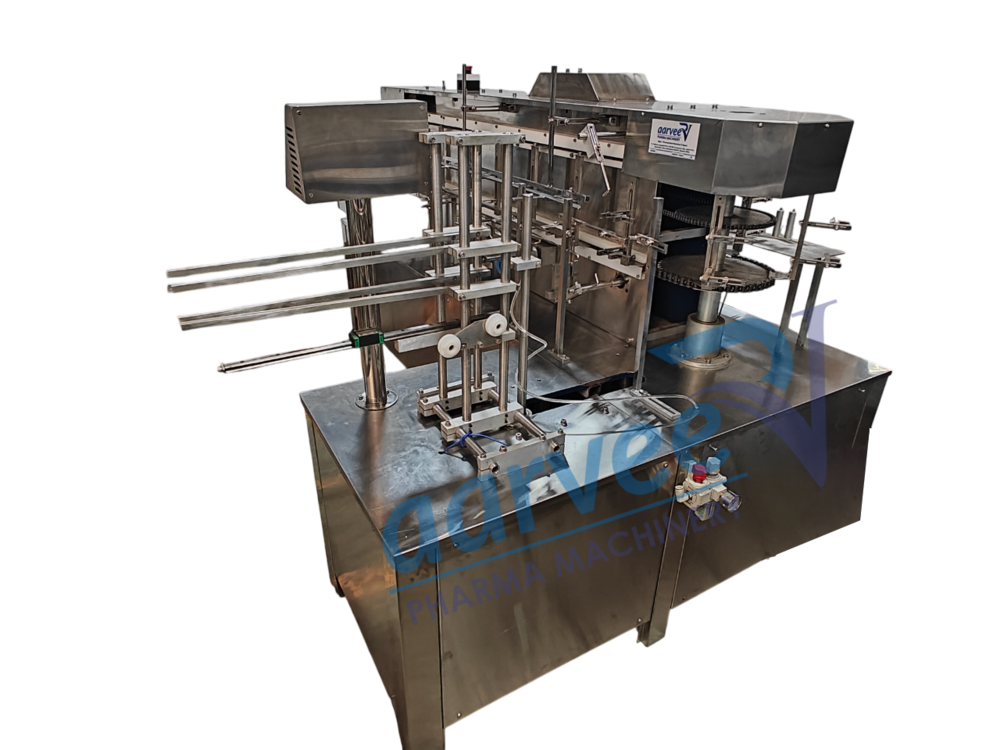

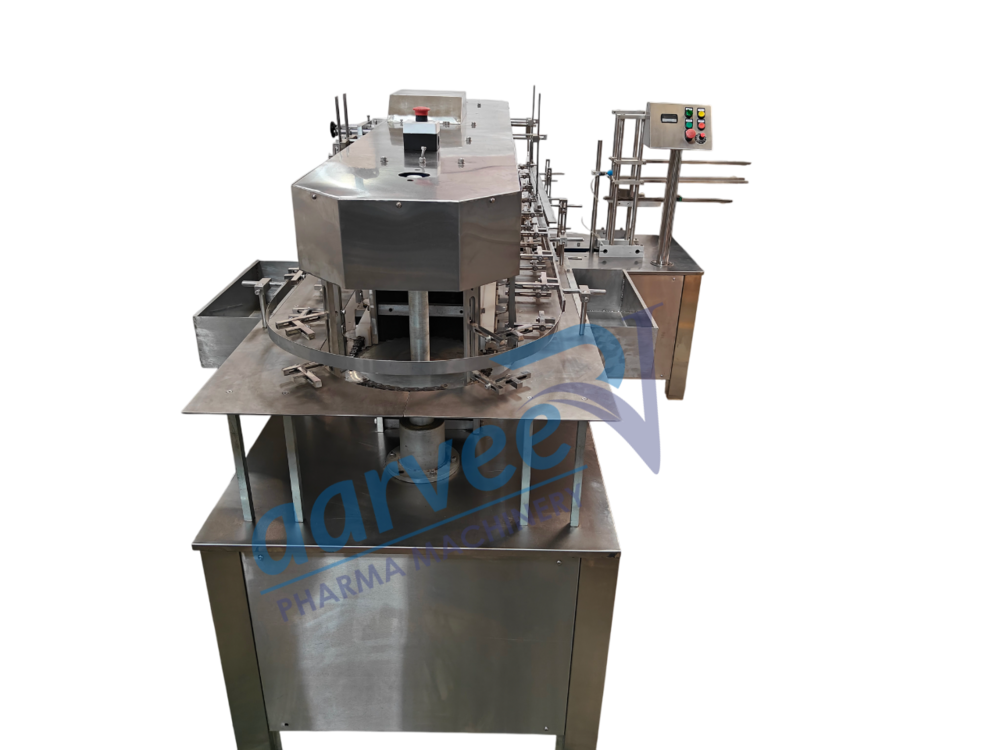

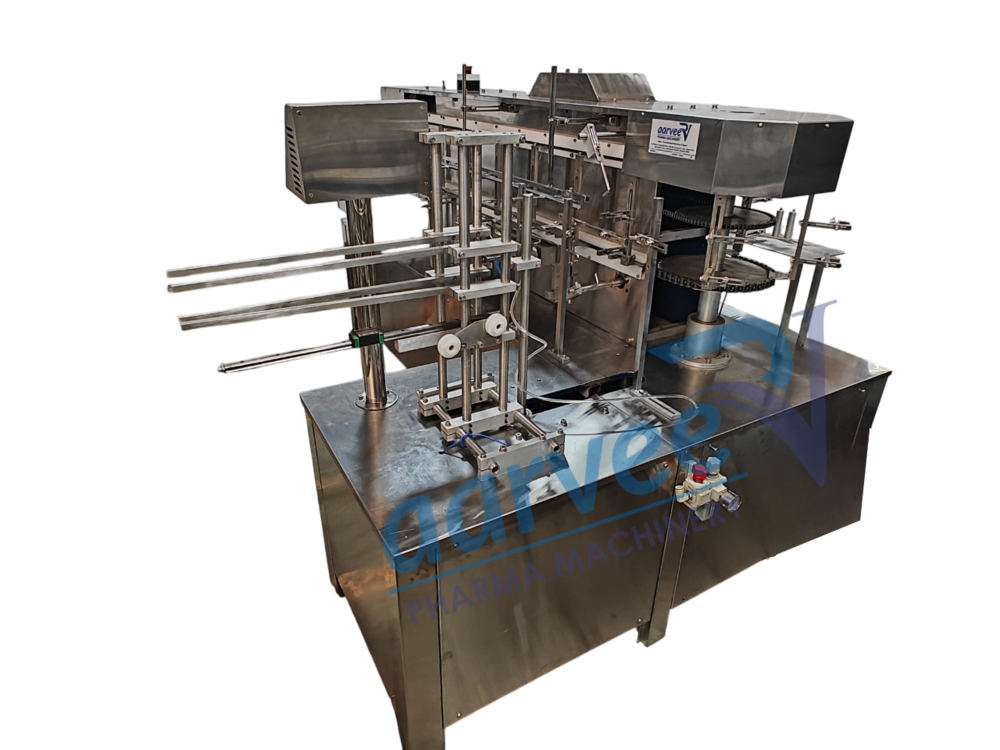

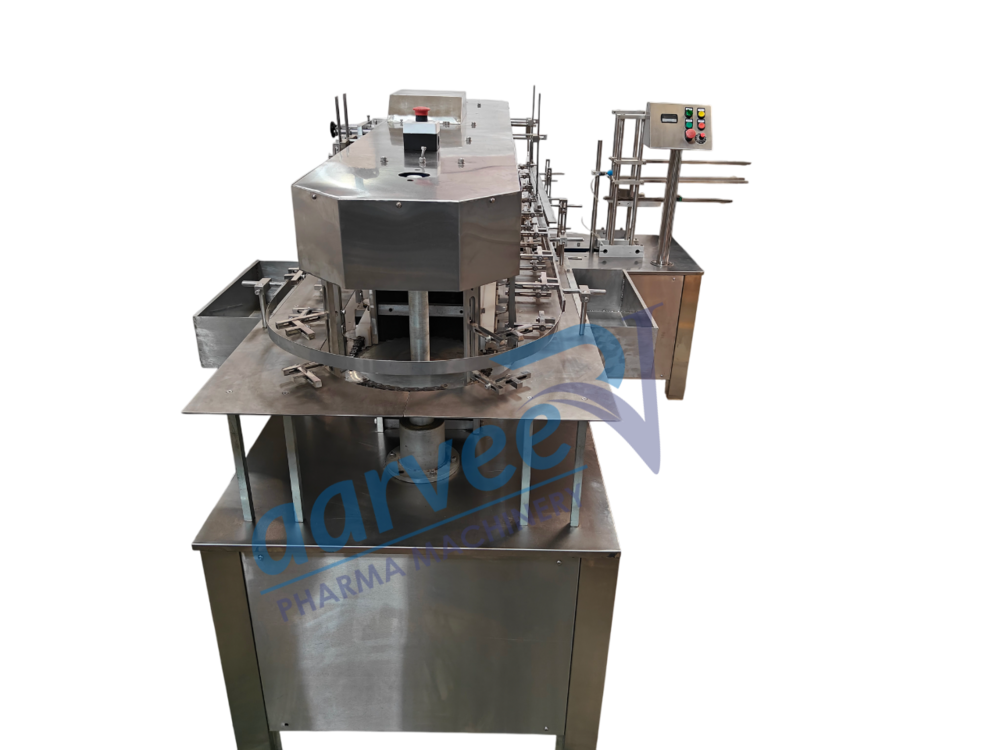

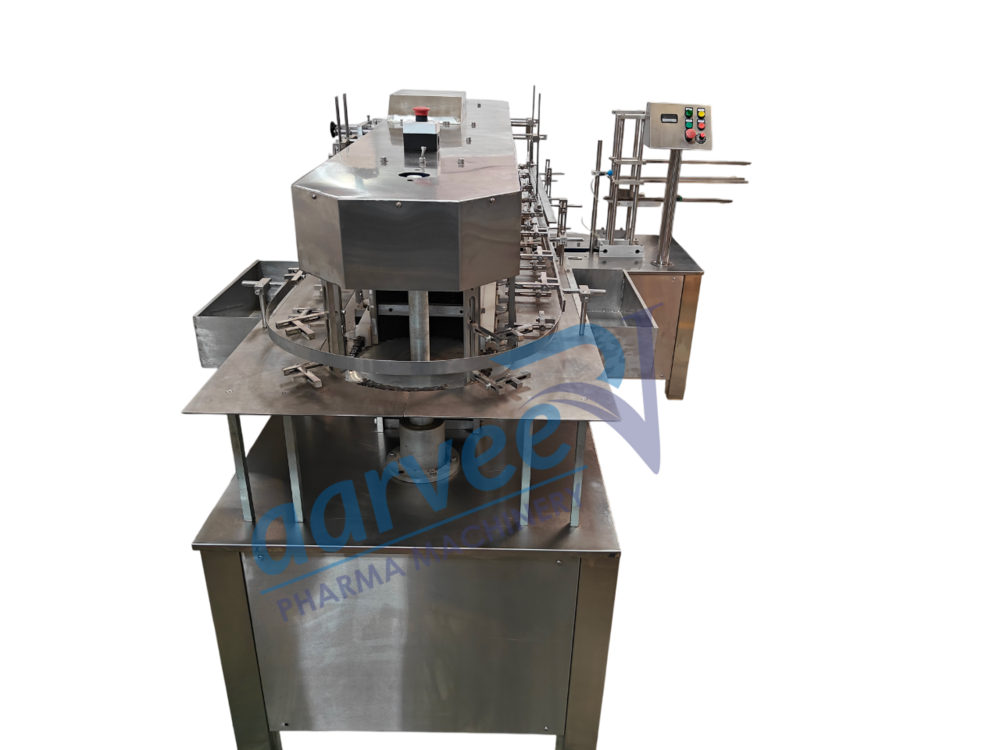

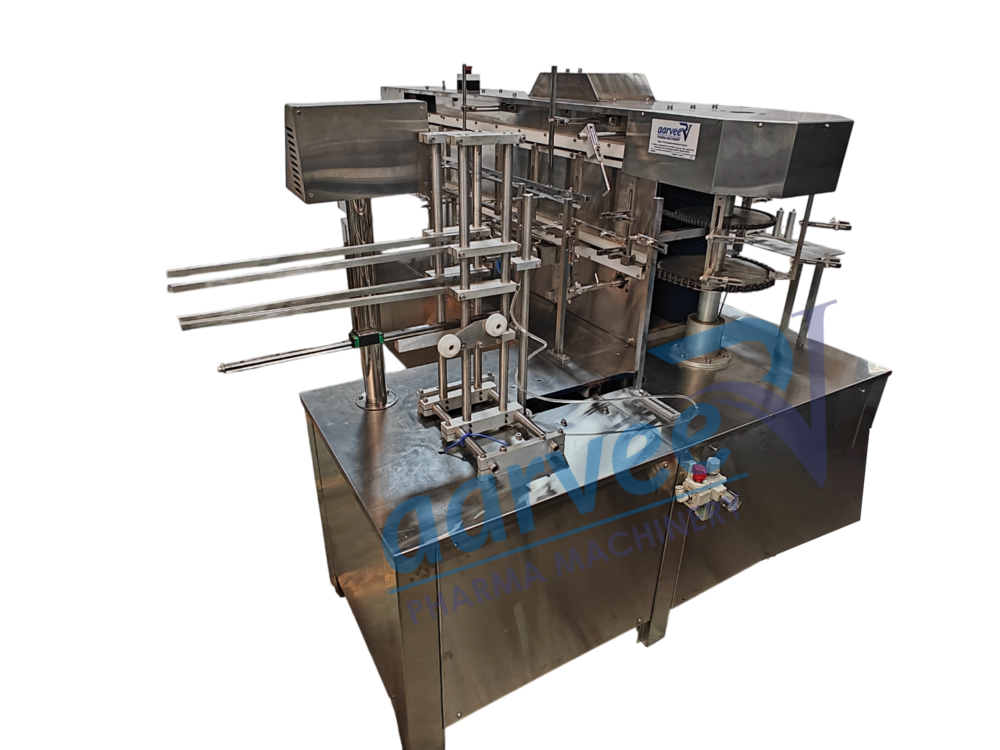

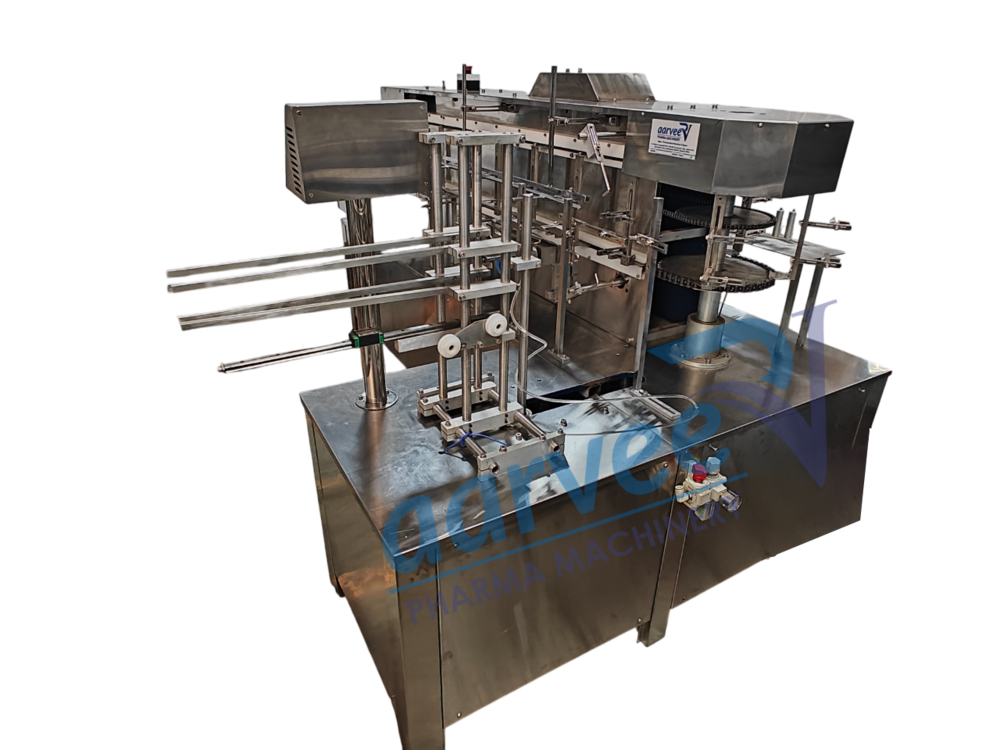

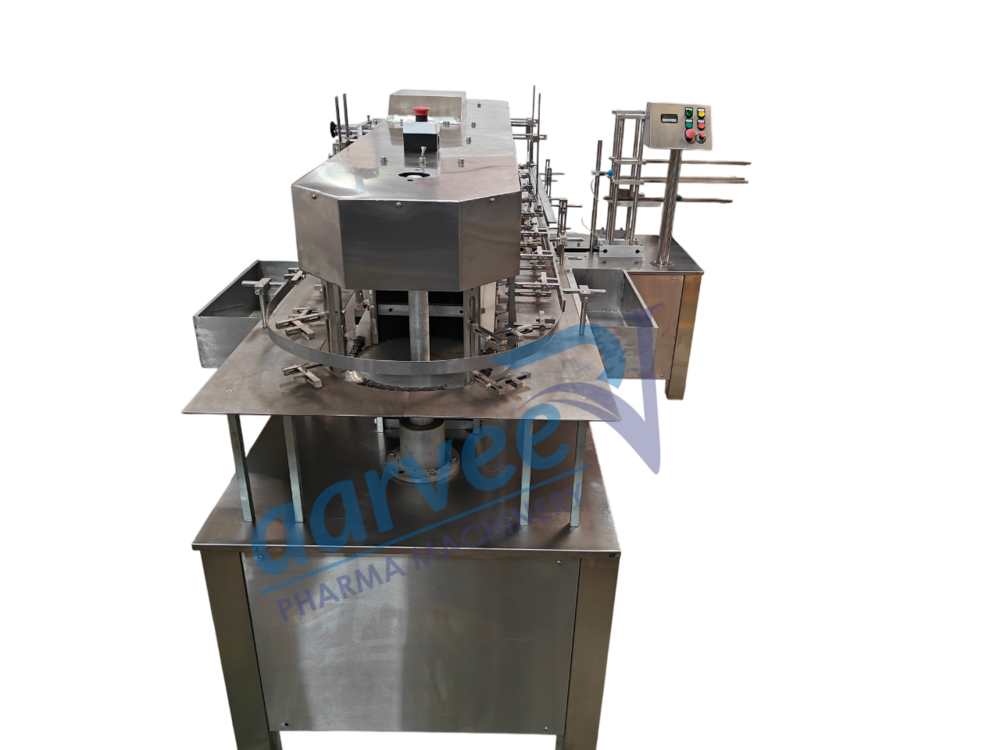

Semi Automatic Linear Cartoner

Product Details:

- Power Supply 1 Phase, 230 V, 50 Hz

- Application Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products,

- Features High-speed operation: 100120 cartons per minute, Semi-automatic with 2 or 4 operators, Fully mechanical (no PLC or HMI), Cost-effective and easy to maintain, Tuck-in or hot-melt glue sealing options, Sturdy and durable construction, Adjustable for various carton sizes, Simple and user-friendly operation

- Usage Carton packaging for various industries. e.g. Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products,

- Noise Level 85 db

- Type Packaging Line

- Material SS-304

- Click to View more

Semi Automatic Linear Cartoner Price And Quantity

- 1 Unit

- 1000000.00 - 1500000.00 INR/Unit

- 1400000 INR/Unit

Semi Automatic Linear Cartoner Product Specifications

- 70 Pcs/hr

- High-speed operation: 100120 cartons per minute, Semi-automatic with 2 or 4 operators, Fully mechanical (no PLC or HMI), Cost-effective and easy to maintain, Tuck-in or hot-melt glue sealing options, Sturdy and durable construction, Adjustable for various carton sizes, Simple and user-friendly operation

- 230 Volt (v)

- Highly Efficient Less Power Consumable Durable

- Packaging Line

- Other

- 800 Kilograms (kg)

- Carton packaging for various industries. e.g. Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products

- 3 X 1.5 X 1.5 Meter (m)

- Silver

- Mechanical

- 1 Phase, 230 V, 50 Hz

- No

- Semi-Automatic

- 1 Year

- Pharmaceuticals, Cosmetics, Food Products, Stationery Items, Homecare Products

- PLC Control

- 1 Horsepower (HP)

- SS-304

- Other

- 85 db

Semi Automatic Linear Cartoner Trade Information

- Cash in Advance (CID)

- 1 Unit Per Month

- 45 Days

- Contact us for information regarding our sample policy

- Wooden Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015, GMP and IEC Certifications

Product Description

Semi Automatic Linear Cartoner - offered by AARVEE PHARMA MACHINERY, is a semi-automatic, cost-effective cartoner machine designed for medium to high-speed packaging applications. Available in 2-operator and 4-operator configurations, this machine provides an efficient and less complex solution for manufacturers seeking speed, reliability, and ease of operation without the need for advanced automation. With an operational speed of 100 to 120 cartons per minute, the machine is ideal for industries such as pharmaceuticals, food, cosmetics and consumer goods, efficiently handling products like bottles, vials, jars, pouches and sachets. The manual product loading stations allow operators to place products into cartons, while the machine automatically handles carton erection and closing on both flaps. Designed for simplicity and durability, this PLC-free and HMI-free cartoning solution reduces maintenance complexity while ensuring smooth operation. Manufacturers can choose between tuck-in or hot-melt glue sealing, offering flexibility to meet various packaging requirements. The 2-operator model is suited for moderate production demands, while the 4-operator model is ideal for higher output requirements, making it a scalable solution for growing businesses. With its rugged construction, easy operation and minimal maintenance needs, the Linear Vertical Cartoning Machine is the perfect choice for manufacturers looking for a semi-automatic, high-speed and cost-effective cartoning system that maximizes efficiency with minimal automation.

Key Features:

1. Medium to High-Speed Performance - Achieves a speed of 100 to 120 cartons per minute, ensuring efficient packaging for medium to large-scale production.

2. Semi-Automatic Operation - Requires 2 or 4 operators for manual product loading while the machine automatically performs carton pick-up and carton closing on both flaps.

3. PLC-Free & HMI-Free Design - A simplified mechanical system eliminates the need for complex electronics, making it easy to operate, maintain, and troubleshoot.

4. Cost-Effective & Less Complex Solution - Ideal for manufacturers looking for a high-speed yet affordable cartoning machine with minimal automation.

5. Multiple Carton Closing Options - Offers tuck-in or hot-melt glue sealing, providing flexibility for different packaging needs.

6. Sturdy & Durable Construction - Built for long-term reliability with minimal maintenance requirements.

7. Customization for Different Carton Sizes - Adjustable settings to accommodate a variety of carton dimensions.

8. User-Friendly Operation - Simple mechanical controls enable quick setup, easy adjustments and smooth operation.

9. Scalable Solution - Available in 2-operator and 4-operator configurations, allowing manufacturers to scale production based on demand.

Optional Features:

1. Automatic Bottle/Leaflet/Pouch Feeder Mechanism

2. Hot Melt Glue System with Precision Control - Ensures secure and precise glue application for carton sealing.

3. Batch Coding & Printing Integration - Allows date, batch number, or serialization printing for regulatory compliance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+